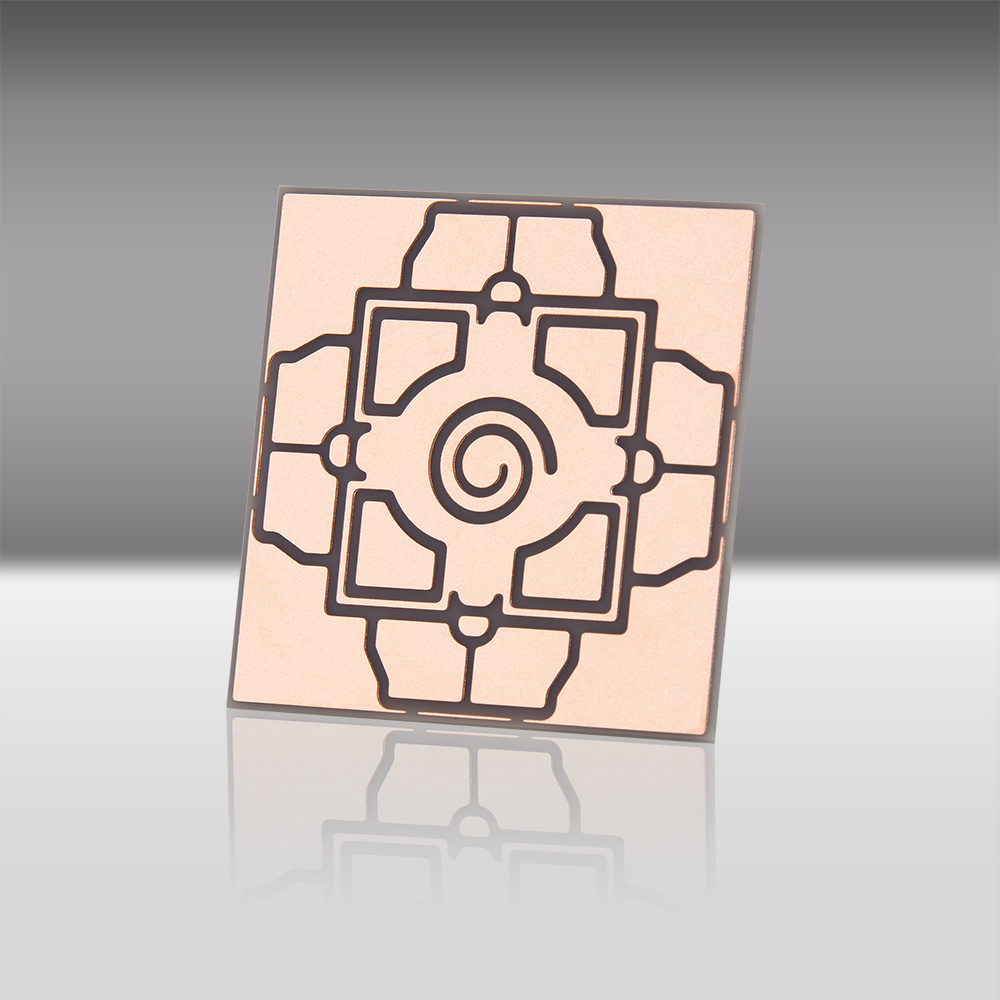

Belonging to the series:

DBC-ZTA

Using zirconia-containing ceramic sheets to enhance toughness, with good thermal and mechanical properties, and excellent thermal shock resistance.

Using zirconia-containing ceramic sheets to enhance toughness, with good thermal and mechanical properties, and excellent thermal shock resistance.

| Process Type | Unit | DBC | |

| Wet Method, Dry Method | |||

| Ceramic Type | - | ZTA | |

| Ceramic Strength | Mpa | >600Mpa | |

| Thermal Conductivity of Ceramic | W/m.K | >26 | |

| Breakdown Strength | KV/mm | >15 | |

| Peel Strength | N/mm | >5 | |

| Thermal Shock | Times | >90 times | |

| Surface Treatment | - | Bare Copper/Solder Mask/Nickel Plating/Nickel Gold Plating | |

| Ceramic Thickness Selection | mm | 0.25, 0.32 | |

| Copper Thickness Selection | mm | 0.2, 0.25, 0.3, 0.4 | |

Key words:

Direct Bonded Copper Substrate

Active Metal Brazed Copper Substrate

Related Products

Product Consulting